- sales@agein.in

- info@agein.in

- +91-9873634995

- +91-9667200163

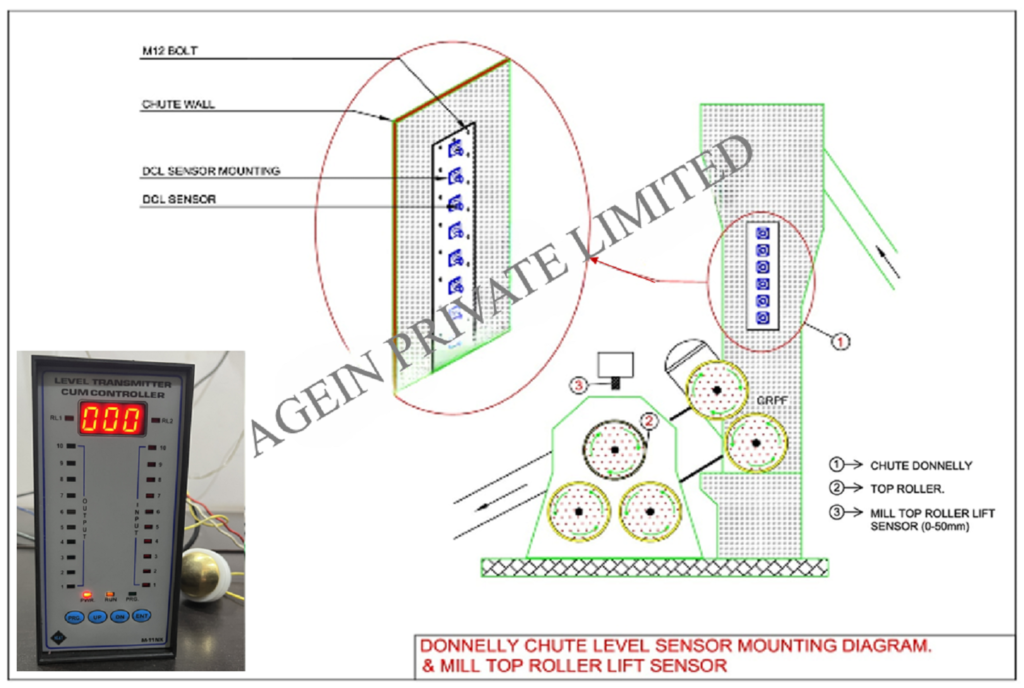

Donnelly Chute Level Transmitter & Sensors

Capacitive Type Donnelly Chute Level Sensor

Donnelly Chute Level Transmitter & Sensor

- Capacitive sensors are used for the non-contact detection of any objects.

- In contrast to inductive sensors, which only detect metallic objects, capacitive sensors can also detect non-metallic materials.

- Typical applications are in the wood, paper, glass, plastic, food and chemical industries. Capacitive sensors for example monitor that the contents of a cardboard box are complete or check the presence of the non-metallic caps.

- Latest and modern technology based Donnelly Chute Level Measurement through Capacitive type sensor and solid state digital indication system specially designs for measurement and display of Donnelly Chute level.

- Capacitive Type Sensors shall be mounted on side of Mill Donnelly Chute and Digital indicators are designed for Panel mounting in industry environment.

- The digital indicator indicate the instantaneous value of Mill Donnelly Chute level (0-100%) are to be measured through Capacitive type Sensors. These Rugged and highly accurate sensors avoid the difficulties arising due to faulty signals raised by Infra Red/ conductivity / LDR / Normal Photo Sensors. These sensors sense only genuine level through the raining Bagasse into Mill Donnelly Chute. Please read the instructions carefully before installing the system.

Quick Enquiry

- 1756 Control Logix Controller

- 1769 Compact Logix Controller

- 1766 MicrloLogix Controller

- 2080 Micro 800 Controller

- 1756 I/O Modules

- 1794 I/O Modules

- 1769 I/O Modules

- 1734 I/O Modules

- 1762 I/O Modules

- 2080 I/O Modules

- 2085 I/O Modules

- 1756 Controllogix I/O Adapter

- 1794 Flex IO Adapter

- 1769 Compact I/O Adapter

- 1734 Point I/O Adapter

- PowerFlex-4 Compact AC Drive

- PowerFlex-4M Compact AC Drive

- PowerFlex-40 Compact AC Drive

- PowerFlex-40P Compact AC Drive

- PowerFlex-70 AC Drive

- PowerFlex-70 AC Drive

- PowerFlex-523 AC Drive

- PowerFlex-525 AC Drive

- PowerFlex-527 AC Drive

- PowerFlex-400 AC Drive

- 1606-XLS Performance Power Supply

- 1606-XLE Essential Power Supplies

- 1606-XLP Compact Power Supplies

- 1606-XLB Basic Power Supplies

- 1769-PA2 L3x & L3y CompactLogix Power Supplies 120/240 VAC Input 2 Amp @ 5 VDC Output

- 1769-PB2 L3x & L3y CompactLogix Power Supplies 24 VDC Input 2 Amp @ 5 VDC Output

- 1769-PA4 L3x & L3y CompactLogix Power Supplies 120/240 VAC Input 4A @ 5VDC, 2A @ 24VDC

- 1769-PB4 L3x & L3y CompactLogix Power Supplies 24VDC Input 4A @ 5VDC 2A @ 24VDC

- 1734-EPAC 120V AC Power/Bus Extension Module

- 1734-EP24DC 24V DC Power/Bus Extension Module

- 2711R- PanelView 800 HMI Terminal

- 2711P- PanelView Plus 6 HMI

- 2711P- PanelView Plus 7 HMI

- 2711T- MobileView Tethered

- 2711P- PanelView5510 Terminal

- 2711P- PanelView5310 Terminal

- 1769-PA2 : L3x & L3y CompactLogix Power Supplies 120/240 VAC Input 2 Amp @ 5 VDC Output

- 1769-PB2 : L3x & L3y CompactLogix Power Supplies 24 VDC Input 2 Amp @ 5 VDC Output

- 1769-PA4 : L3x & L3y CompactLogix Power Supplies 120/240 VAC Input 4A @ 5VDC, 2A @ 24VDC

- 1769-PB4 : L3x & L3y CompactLogix Power Supplies 24VDC Input 4A @ 5VDC 2A @ 24VDC

1756-PA72 : ControlLogix, 85-265 VAC Power Supply (10 Amp @ 5V)

- 1756-PA75 : ControlLogix, 85-265 VAC Power Supply (13 Amp @ 5V)

- 1756-PB72 : ControlLogix, 19-32 VDC Power Supply (10 Amp @ 5V)

- 1756-PB75 : ControlLogix, 19-32 VDC Power Supply (13 Amp @ 5V)

Donnelly Chute Level Transmitter

This is micro-processor based Donnelly Chute level Transmitter with isolated o/p (4-20 mA), 10nos digital optical o/p and 2 relay control .The instrument is field programmable and user friendly. In this Instrument user can set sensor sensitivity, sensor level selection, sample delay time and relay set point etc. The user can set level 2-10 then instrument automatically tunes for o/p 4-20 mA and display 0-100%. The instrument has five settable parameters like rL1,rL2,snt,trl,Lst. The Instrument reads input level in sequence 1 to 10 if misplaced any level then it will not show above levels. Operations Manual – Donnelly Chute Level Transmitter with Modbus Communication Model M11 NX

Operations Manual – Donnelly Chute Level Transmitter with Modbus Communication Model M11 MAX

Parameters

Snt: Sensor Sensitivity adjustment

Lst: Level Sensor selection (2-10)

Trl: sample Delay adjustment

RL1 and rL2 : Relay set point (0-100)

snt(sensitivity adjustment Parameter)

In this parameter user can set sensitivity of every (1-10 sensor) level sensor through key pad. The sensor value can be set in this parameter 93(Max.) to (185min.) sensitivity and it is normally set 100 value of every sensor.

If snt set 93 then i/p led direct on without input connection.

Lst(level selection parameter)

The user can be set input level 2-10 then instrument automatically tune for o/p 4-20 mA and display 0-100%

Trl = 20 set

rL1,rL2 : Relay set point value

Terminal Details

S1 to S10 : i/p for probe type level sensor

GND : Common terminal of probe sensor (Donnelly chute sensor)

L1 to L10 :o/p for isolated digital out put to plc

+24vdc : +v common (+24 vdc) for plc digital i/p

O/p 4-20 mA : mA output (isolated)

P : common terminal of Relay

N/O : Normaly open terminal of Relay

N/C : Normaly close terminal of relay

L : Phase of 220v AC @50/60Hz

N : Neutral

E : Earth

Specifications

Main (auxiliary supply) : 220vAc +-15% @50 Hz

O/P (Analog) : isolated 4-20mA

O/p (digital : isolated digital output (L1 to L10)

Relay set value : 000-100 settable

Display range : 0-100% according select sensor level (2-10) settable

Time delay setting : 001-100 ms settable

Input :10nos. Probe sensor (digital i/p)

Digital i/p / o/p : Indicate by LED as fitted on the front panel

LED : Red Led for i/p, Green Led optical digital o/p

Control Relay : one pair normally open potential free contact: @ 5A at 240v AC

Overall size : 96x194x223 mm (WxHxD )

Panel cutout : 184X92mm(HxW)

Configuration

1st press both PRG+ DN key for 5 seconds then display rL1 press ENT key

display last load value if change then Use up/dn key and press ENT key

display rL2 press ENT key display last load value if change then use up/dn key And press ENT key

display snt press ENT display 001(it means level 1 select to adjust sensitivity) press ENT

display last load value of sensor 1 sensitivity , if you want change value then use up/dn if value decrees (it means sensitivity higher side(93 max.) ) if value increase (it means sensitivity lower side(185 min.) if you want to store modified value then press and hold PRG key after press ENT key now release both key now modified value has been stored .

If you do not want to change in this parameter then use only ENT key, if press only ENT key it means by pass snt parameter, if press PRG key and ENT key it means modified value stored and display snt for next level sensor sensitivity calibration And same process apply for level 1 to level 10 after that, Next parameter Lst display press ENT key display last level select if change (2-10) then use up/dn key press ENT key display trL press ENT key display last value and set 20 and press ENT key and now exit configuration mode.

Wait for Run led on (Run led on it means ,system in run mode.)

Troubleshooting

1. Fault 01 : If Display Eror1

2. Fault 03 : if Display 100% value on fnd display

3. Fault 02 : if Display Eror2

Fault 01: if Display Eror1 message it means wrong level select, now re-select level in Lst

Parameter (2-10)

Fault 02: if system display Eror2 message it means stored data has be corrupted now switch off of power and press and hold up and ENT key now switch on of power and hold up to counting display 1 to 9 now release Both key.

Fault 03 : If 100% value On Fnd display and all input led(red colored) glow without input level connection, it means sensitivity low than 100 value, now go to calibration process & select snt parameter and set 100 value of every sensor.

Note: If snt parameter set93 then i/p led direct on without input connection.